ADVENTURE-READY FRAMES

Each Costa frame offers its own performance advantages and style features for lightweight, durable eyewear that fits every occasion.

Our bio-resin frames hold their shape under the harshest conditions.

The Bio-Resin Raw Material Process is part of our Kick Plastic initiative to reduce our carbon footprint and protect our planet's waters.

INNOVATIVE SWEAT MANAGEMENT SYSTEM*

1. New ventilation ducting allows airflow through the end piece of the frame, which helps to keep you cool, reduces lens fogging, and works in conjunction with the sweat management template channels. **

2. Channels run the length of the temple that enable airflow from the vents to cool, wick away sweat and moisture, and drain through the openings on the temple tips.

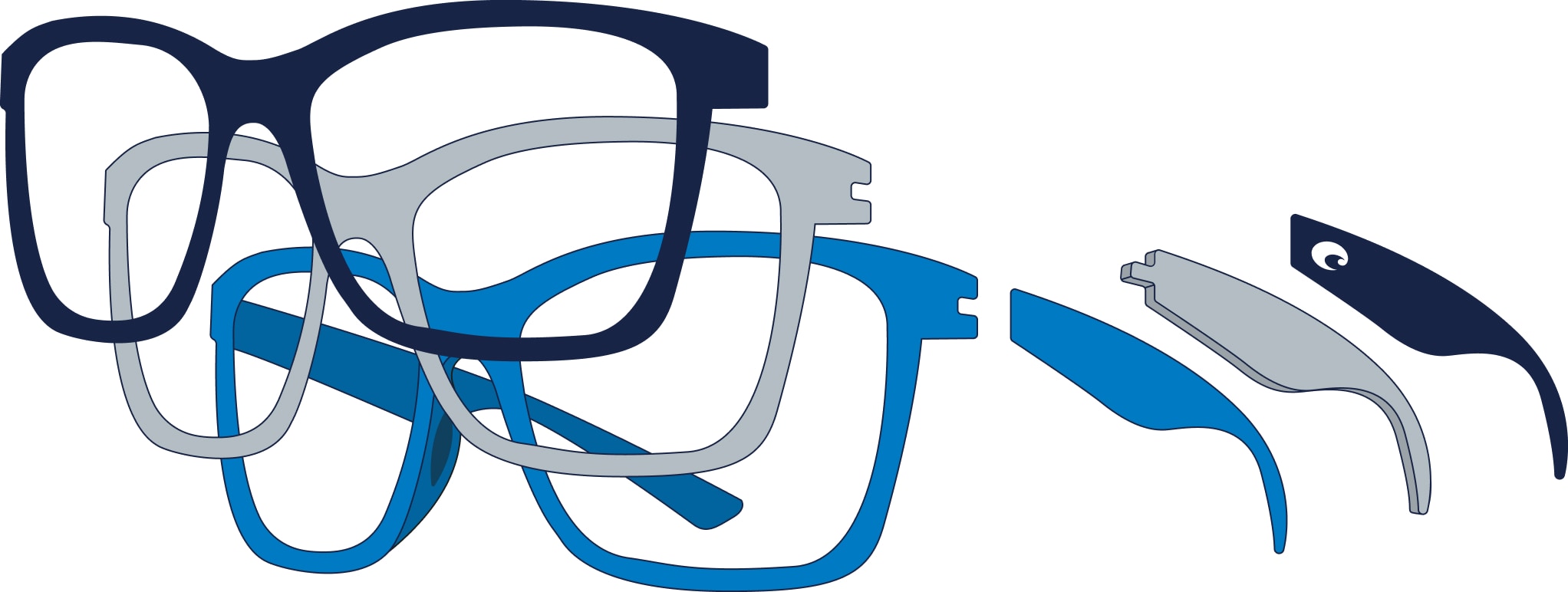

TRI-LATERAL FUSION

This original technique is created by bonding together two or three distinct colors into one frame, allowing you to see multiple unique color combinations in a chip-proof frame.

- *Each layer is comprised of solid color bio-resin. The result is a highly durable frame with chip-proof color.

- *Original bilateral and trilateral styles are created by bonding together two or three distinct colors into one frame.